Material Choices 101: Which Materials and Why?

When choosing materials for a product, it’s not just about the aesthetic, it’s about how they feel, perform, and even age over time. Think about the smooth, cool touch of metal, the soft flexibility of silicone, the grippy resilience of rubber, or the lightweight versatility of plastic. Each material has its own unique properties that affect durability, comfort, and function. Ever wondered why high-end electronics often use brushed aluminum instead of plastic? Or why kitchen tools sometimes have rubberized grips? These choices aren’t random—they’re all about optimising texture and finish for the best user experience. Whether in design, manufacturing, or everyday life, understanding material finishes helps us make smarter choices about the products we use and create.

Material Choice

Every product we use is made from materials chosen for their unique properties, and that choice isn’t just about looks, it affects durability, functionality, and even sustainability.

Metals like aluminium and stainless steel offer strength, heat resistance, and a premium feel, making them ideal for everything from smartphones to kitchen appliances.

Plastics are lightweight, versatile, and cost-effective, used in everything from packaging to high-performance engineering components. Silicone is flexible, heat resistant, and hypoallergenic, perfect for medical devices, bakeware, and even wearable tech.

Rubber, with its excellent grip and shock absorption, is essential in tyres, footwear, and industrial applications. Each material has its own strengths and trade-offs, and understanding these differences helps designers, engineers, and consumers make smarter choices.

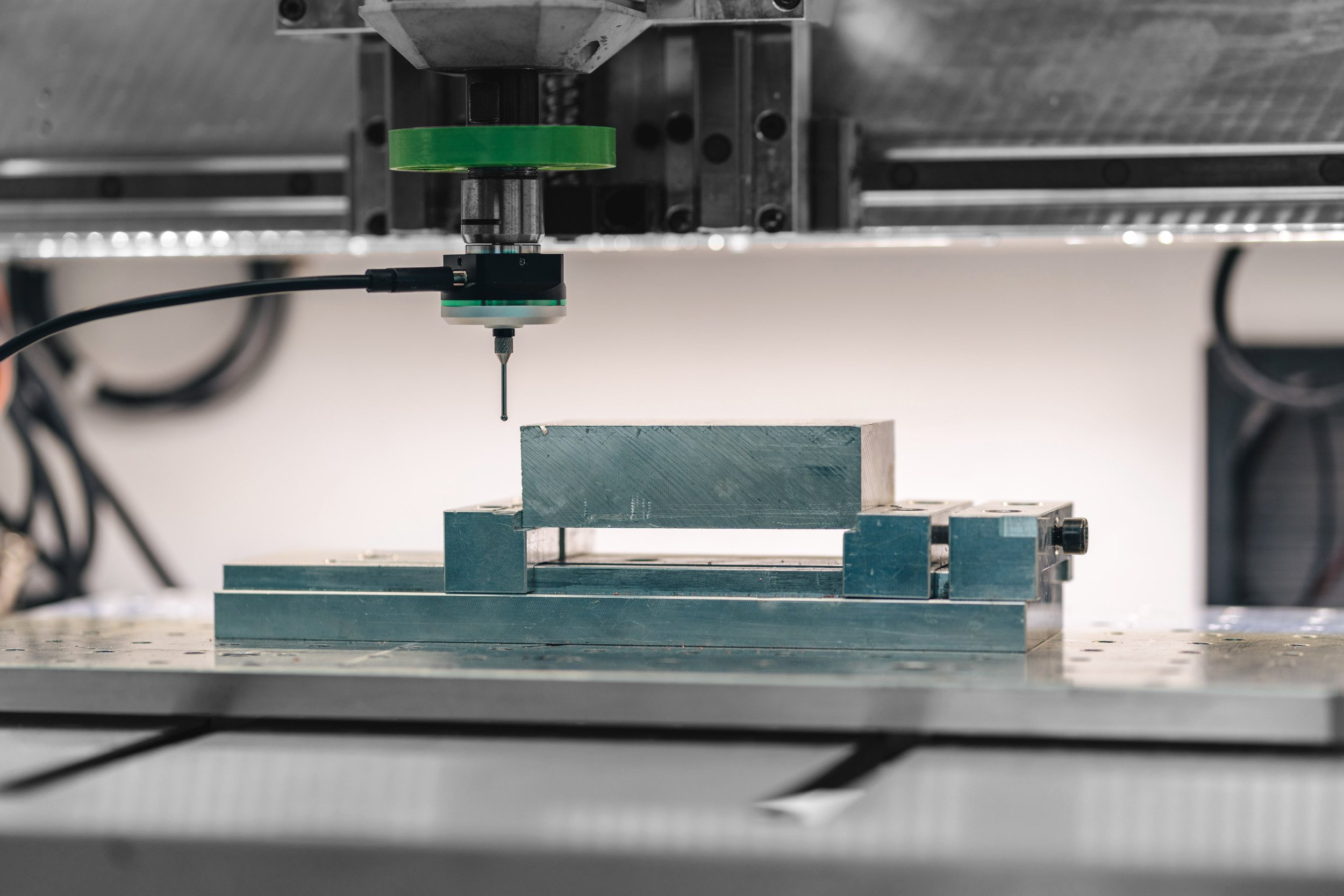

A CNC machine being calibrated at the Engineering Lab HQ to precision-cut aluminium stock material.

SLA 3D printing, shown on the right, delivers exceptional print quality, enabling the creation of premium, custom parts directly on site.

Finishes and Aesthetics: More Than Just Looks

The finish of a material isn’t just about aesthetics, it affects durability, texture, and even functionality. The right finish can protect against wear and tear, improve grip, or enhance corrosion resistance.

Anodising, for example, is commonly used on aluminium to create a hard, oxide layer that improves durability and allows for vibrant colouring without peeling or chipping.

Painting and powder coating offer a protective and decorative layer on metals and plastics, with options for glossy, matte, or textured finishes.

Plastic dipping creates a rubber like coating that improves grip and adds a protective barrier, often used for tools and automotive parts.

Silicone forming allows for soft-touch finishes in consumer electronics, kitchenware, and medical devices, offering both comfort and flexibility.

In the metal industry, galvanisation (coating steel with zinc) prevents rust, while stainless steel uses chromium or anodic protection to resist corrosion. These processes not only extend a product’s lifespan but also define how it looks and feels. Whether designing a rugged outdoor tool or a sleek smartphone, the right finish can make all the difference in performance and user experience.

Notice the anodised finish on the Aluminium Otect Q-CAP, which perfectly complements the sleek, premium aesthetic of the Leica Q3 Camera.

This design showcases a thoughtful combination of materials: metal bolts for enhanced durability, rubber wheels to protect surfaces and ensure smooth movement, and impact resistant plastic to keep production costs low while maintaining a sleek, white finish.

Sustainable Materials: Balancing Performance and the Planet

As industries shift towards more sustainable practices, material choice plays a huge role in reducing environmental impact.

Recycled metals like aluminium and steel help cut down on mining and energy use, while bioplastics made from renewable sources like corn starch or algae offer an alternative to traditional petroleum based plastics.

Natural materials like bamboo, cork, and organic cotton are gaining popularity for their biodegradability and renewability. Even high performance materials like silicone are being re-engineered to be more eco-friendly, with some manufacturers developing recyclable or bio-based versions. The key challenge is balancing sustainability with performance eco-friendly materials must still be durable, functional, and cost effective. As technology advances, we’re seeing exciting innovations in material science that bring us closer to a truly circular economy.

Designing for Longevity: The Overlooked Side of Sustainability

When we talk about sustainability, the focus is often on using recycled or biodegradable materials, but one of the most impactful ways to reduce waste is simply designing products that last. A well designed product, built with durability and functionality in mind, can stay in use for decades or even centuries, drastically reducing the need for replacement and cutting down on resource consumption.

Think about cast iron cookware, which can last for generations, or solid wood furniture that ages beautifully over time. Even well engineered electronics (a quick shout out to Panasonic for their Technics 1200 and 1210 series turntables) and quality stainless steel tools can far outlive cheaper, disposable alternatives. Instead of designing for planned obsolescence, the future of sustainability should embrace products that are repairable, modular, and built to withstand years of use. In many ways, the greenest product is the one you never have to replace.

The thick aluminium chassis of the EL4P is built for long-lasting durability, with an end-use design that is fully recyclable.

Prototyping with recyclable plastic helps reduce waste, while delivering the final product in sleek anodised aluminium strikes a balance between cost efficiency and premium quality—benefiting both the environment and the producer.

Bringing It All Together: Smart Material Choices for Better Design

From the materials we choose to the finishes we apply, every decision in product design impacts durability, functionality, and sustainability. A well chosen material ensures strength and purpose, while the right finish enhances longevity and user experience. Whether it’s anodised aluminium, galvanised steel, or silicone-coated surfaces, these details define how a product looks, feels, and lasts. True sustainability isn’t just about using recycled materials, it’s about creating products that stand the test of time. By designing with longevity, functionality, and aesthetics in mind, we can craft items that don’t just serve a purpose today, but for generations to come.